Foundry – Quality

To ensure international quality standards the entire production process is subjected to stringent quality check, quality control & assurance starts right from raw materials until the delivery of finished castings.

With our quality experts we do inspection on sample casting as per our inspection plans, to ensure the dimensions as per drawings, process variables and wall thickness. We export Industrial valve and pump castings to European market under 3.1 certification and also under 3.2 as per customer requirement.

CHEMICAL TESTING

Chemical testing is done to confirm Material grades and also we have facilities of wet Analysis

- Optical emission direct reading spectrometer iSpark Plus upto 32 channels including low Nitrogen & high Nitrogen and Oxygen elements are available at our facilities.

PHYSICAL TESTING

Physical Testing unit comprises of the following equipments calibrated under third party TUV, BVQI, DNV-GL, Lloyds & IBR.

- Digital Profile Projector Model 300 TE

- Screen – Fine ground glass screen 300 mm x 5 mm with cross lines at 900 Magnification – 10 x Lens

- Workstage –

- Size of Top Plate – 350 x170 mm

- Measuring Traverse XIY axis – 200 x 100 mm

- Working Area – 245 x 120 mm

- Load Capacity – 20 Kgs

- Max -150 mm

- Brinel hardness testing machine with 0-600 BHN range.

Impact Testing

- Impact Testing Machine with capacity of 0 – 300 Joules Charpy, we can perform to low temperature – 196 degree Celsius

- ASTM E23

- ISO 148-1

- Testing temperature up to – 196° C

- Lateral Expansion

UTM – Computerised Electronic Extensometer

- Up to 40 Metric Tons Digital Universal Testing Machine with computerized

- (Capacity 60 Ton 1 No, 40 Ton 2 No.) ASTM A370.

Hardness Tester

- Brinell Hardness Tester

- Rockwell Hardness tester

- (Load: 100 Kgf & 150 Kgf – 1No, 10 kg load-1No)

- Vickers Hardness Tester

- Bend Test

SAND TESTING

Sand Testing process tests AFS Number, moisture content, clay content, etc.

- Permeability

- Sieve Analysis

- AFS Number

- Clay content

- Moisture content

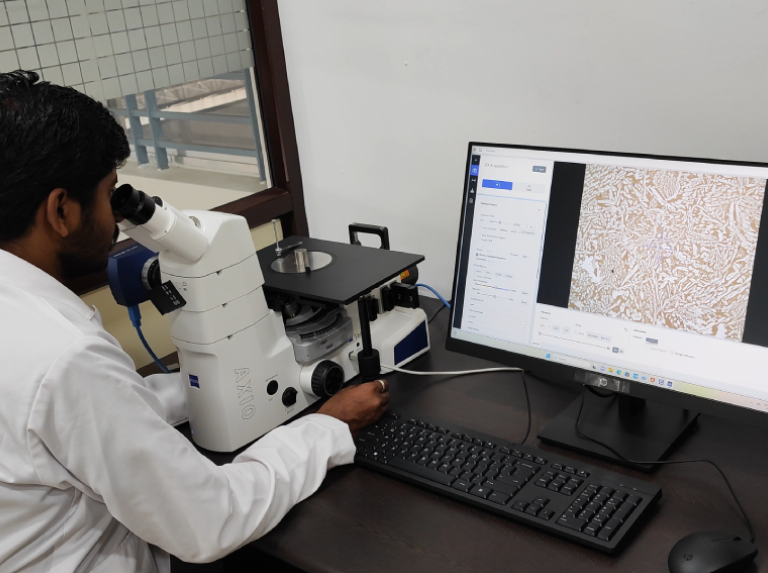

METALLOGRAPHIC EXAMINATION

Computerized microscope to analyze and verify the micro structure of steel castings produced as per ASTM E562 Standard

CORROSION TESTING

Equipped to perform inter granular corrosion testing as per ASTM A262 Pratice, Wet analysis, Pitting Corrosion testing as per ASTM G48 Method – A

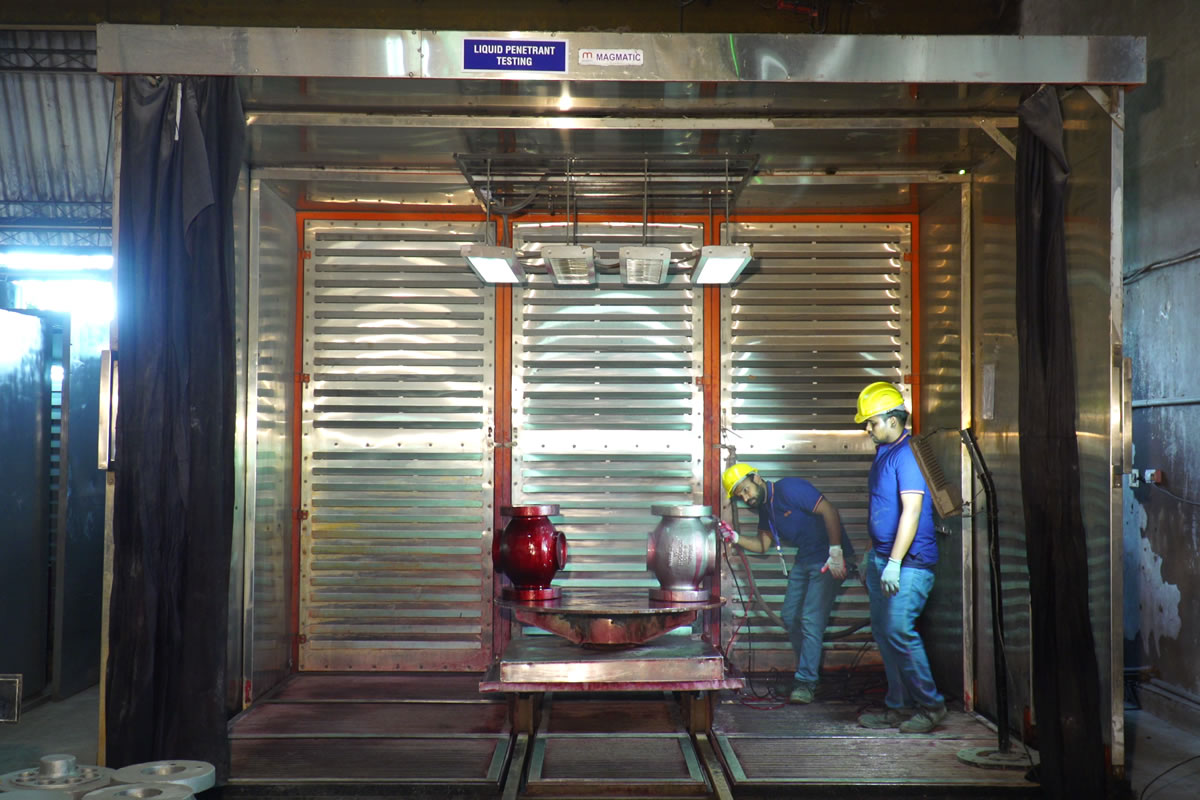

NON-DESTRUCTIVE TESTING

We have in-house facilities of Ultrasonic Testing, Magnetic Particle Testing, Dye penetrate Testing, Positive Materials Identification (PMI) for raw material check, Ferritoscope meter check for Ferrite Content and Radioactive Contamination for on casting & inspection, image analyzer testing on casting. Radiography Testing with Iridium 192 & Cobalt 60. Radiographic films are reviewed by Level II – persons certified as per SNT TC IA/ISO 9712 Level-II.

LIST OF MATERIALS

| MATERIALS SPECIFICATION | ASTM | EN 10213 | EN NO | UNS | JIS |

|---|---|---|---|---|---|

| CARBON STEEL | A216 WCB* | GP 240GH* | 1.0619 | J03002 | SCPH2 |

| A216 WCC* | GP280GH* | 1.0625 | J02503 | - | |

| A352 LCB* | G20Mn5 | 1.6220 | J03003 | - | |

| A352 LCC* | G20Mn5* | 1.6220 | J02505 | - | |

| A352 LC3 | G9Ni14 | 1.5638 | J31550 | SCPL31 | |

| IS 1030 Gr.23-45 | - | - | - | - | |

| IS 1030 Gr.26-52 | - | - | - | - | |

| IS 1040 Modified | - | - | - | - | |

| MARTENSITIC | A352 CA6NM | - | - | J91540 | - |

| LOW ALLOY STEEL | A217 WC6* | G17CrMo5-5* | 1.7357 | J12072 | SCPH21 |

| A217 WC9* | G17CrMo9-10* | 1.7359 | J21890 | SCPH32-CF | |

| A217 C5* | GX15CrMo5* | 1.7365 | J42045 | - | |

| A217 CA15 | - | - | J91150 | - | |

| A217 C12* | - | - | J82090 | - | |

| A217 C12A* | - | - | J84090 | - | |

| A217 Gr.WC5 | - | - | J22000 | - | |

| A487 Gr.4C 60K * | - | - | J13047 | - | |

| A743 Gr.CA40 | - | - | J91153 | - | |

| A487 GR.1C | - | - | J13002 | - | |

| DUPLEX STAINLESS STEEL | A995 4A* | GX2CrNiMON22-5-3* | 1.447 | J92205 | - |

| A995 5A* | GX2CrNiMON26-7-4* | 1.4469 | J93404 | - | |

| A995 6A* | GX2CrNiMON25-7-3* | 1.4417 | J93380 | - | |

| PRECIPITATION STAINLESS STEEL | A747 Gr.CB7Cu-1 (H1150 DBL) |

- | - | J92180 | - |

| A747 Gr.CB7Cu-1 (H1075) |

- | - | J92180 | G 5121 Gr SCS24 |

|

| A747MGr.CB7Cu-1 (H900) |

- | - | J92180 | - | |

| STAINLESS STEEL | A351 CF3* | GX2CrNi 19-11* | 1.4309 | J92700 | SCS19 |

| A351 CF3M* | GX2CrNiMo19-11-2* | 1.4409 | J92800 | SCS16 | |

| A351 CF8* | GX5CrNi 19-10* | 1.4308 | J92600 | SCS13 | |

| A351 CF8C* | GX5CrNiNb19-11* | 1.4552 | J92710 | - | |

| A351 CF8M* | GX5CrNiMo 19-11-2* | 1.4408 | J92900 | SCS14 | |

| A351 CG8M | - | - | J93000 | - | |

| A351 CK3MCuN* | - | - | J93254 | - | |

| A351 CN7M* | - | - | N08007 | SCS23 | |

| A479 TYPE-321/ CF8-Ti | - | - | - | - | |

| A890 Gr.CD4MCuN | - | - | J93372 | - | |

| NICKEL BASED ALLOY STEEL | A494 N-12MV | - | - | N30012 | - |

| A494 CW-12MW | - | - | N30002 | - | |

| A494 M35-1* | - | - | N24135 | - | |

| A494 CW-6MC* | - | - | N26625 | - | |

| A494 CU5MCuC* | - | - | N08826 | - | |

| A494 Gr.M25S | - | - | N24025 | - | |

| A494 Gr.CY-40* | - | - | N06040 | - | |

| A494 Gr.M30H | - | - | N24030 | - | |

| A494 Gr.M30C | - | - | N24130 | - | |

| A 494 Gr CW2M | - | - | N26455 | - |

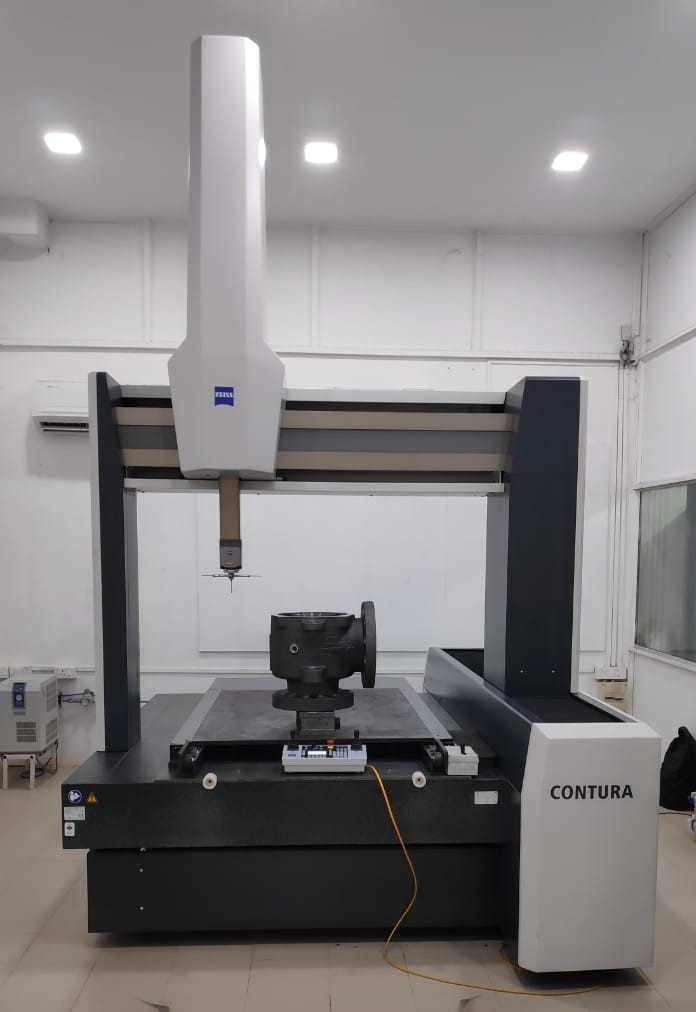

| CARL ZEISS CNC 3D CMM MODEL – CONTURA G2 | |

|---|---|

| Description | Co-ordinate measuring machine |

| Make | ZEISS |

| Type | CONTURA G2 |

| Probe Type | VAST XT AKTIV |

| Specification | X – 1000 mm, Y – 1200 mm & Z – 600 mm |

| MPEE | 1.9 + L/300 |

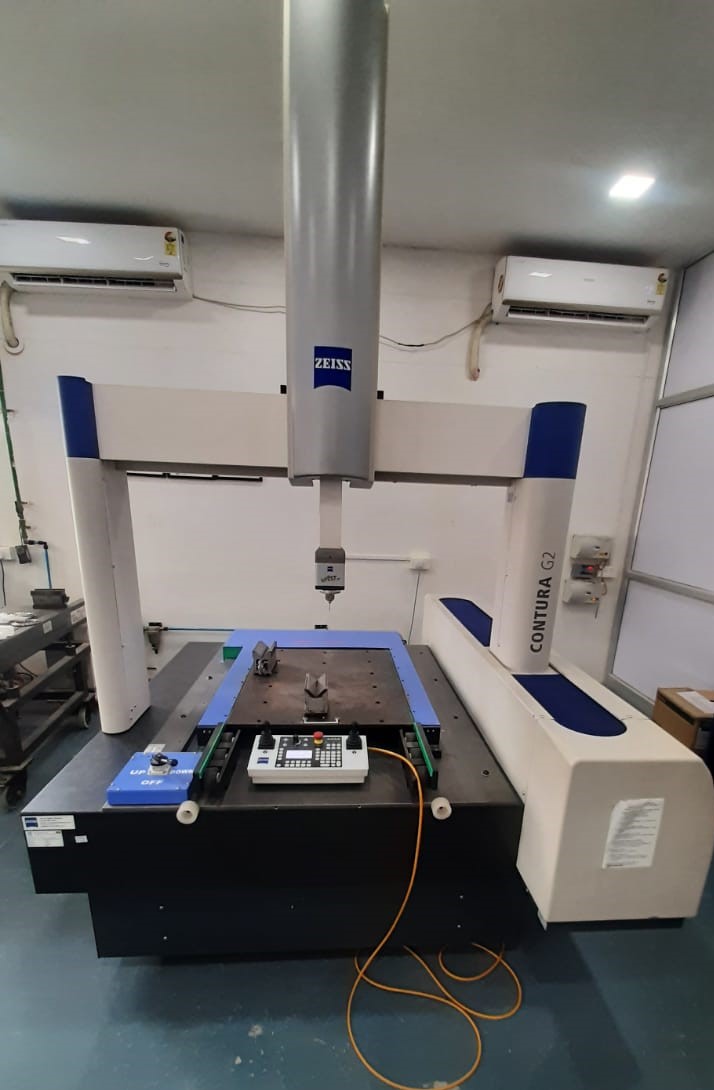

| CARL ZEISS VAST XT CMM MODEL – CONTURA G2 | |

|---|---|

| Description | Co-ordinate measuring machine |

| Make | ZEISS |

| Type | CONTURA G2 |

| Probe Type | VAST XT AKTIV |

| Specification | X – 1200 mm, Y – 1800 mm & Z – 1000 mm |

| MPEE | 1.9 + L/300 |

| 3D Portable CMM – Faro | |

|---|---|

| Description | 3 D Portable CMM |

| Make | FERRO |

| Single point – (Max-Min) / 2 Specification | P06-02 0.02mm (0.0008”) |

| Volumetric (Max Deviation) Specification | P06-02+/-0.029mm (+/-0.00011”) |

| Accuracy | 0.001 |

RECOGNITIONS

We have received recognitions from organizations listed below